One of the most dangerous occurrences you can find when testing a meter is a hot socket. Typically caused by loose connections, hot sockets can be the cause of safety hazards such as house fires. Today, we’ll spend a little time looking at how to guard against hot sockets, as well as the role that energy meter testing equipment plays in maintaining the safety of the meter.

One of the most dangerous occurrences you can find when testing a meter is a hot socket. Typically caused by loose connections, hot sockets can be the cause of safety hazards such as house fires. Today, we’ll spend a little time looking at how to guard against hot sockets, as well as the role that energy meter testing equipment plays in maintaining the safety of the meter.

What is a Hot Socket?

A hot socket is a term used to describe the damaged caused to the meter by overheating. Caused by poor connections, hot sockets become more dangerous the longer they’re left untreated and can be the cause of as many as 1,000 house fires per year. Many times, these issues can be stopped before they start with proper energy meter testing and utilization of proper equipment for testing energy meters.

What Problems Can Hot Sockets Cause?

In addition to the immediate safety concerns, hot sockets also pose a very real financial burden on utility companies, including expensive meter replacements or repairs and payments to homeowners for possible damaged property. Poor maintenance on energy meters can also result in negative publicity for utility companies, as serious hot socket issues can usually be prevented with regular inspection and maintenance.

What Are Common Causes of Hot Sockets?

There are several causes of hot sockets, ranging from sprung jaws, loose wires, worn lines, or outdated equipment being overloaded through use. Whether these issues are the result of wear and tear, damage to the meter, or other factors, it’s crucial to ensure that these elements are inspected on a regular schedule in order to prevent hot sockets from occurring in damaging or costly ways.

How Can I Detect Hot Sockets?

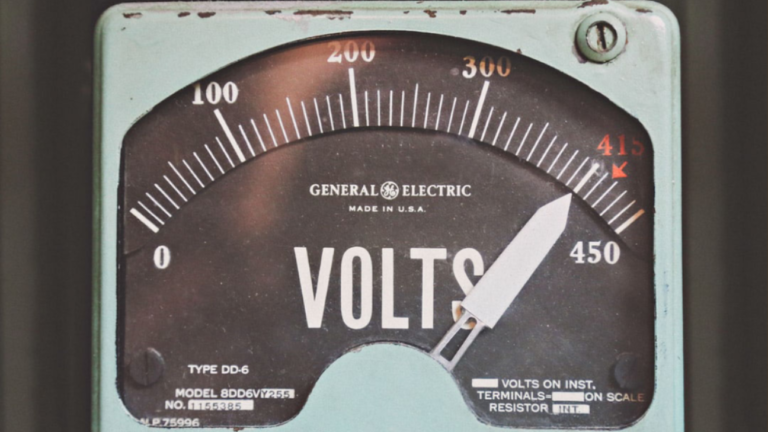

Customers who are experiencing this phenomenon may experience dimmed or flickering lights. To meter inspectors, hot sockets will be visible as damage to the jaws, such as a lack of spring tension or pitting and discoloration. Meter blades may be discolored and wires may be melted. If your energy meter testing equipment is registering higher than average output, it may be important to take the cover off the meter and perform a deeper visual inspection. Another valuable piece of energy meter testing equipment is the indicative socket tester. Designed to detect dangerous wiring errors, these testers protect both the utility company and the end-customer’s equipment from costly or hazardous issues that may arise.

Finding the balance between safety and cost-effective equipment management can be difficult, but with the right set of equipment, it’s possible to protect both the customer and the utility against damage or danger. Electrical services can be a source of confusion and frustration for customers, many still struggling to grasp the ways in which their power use–such as 1,000 watt hours being used to power a 1,000 watt vacuum for an hour–trying to explain loss of power efficiency and potential safety hazards can be a headache. But with regular maintenance, it’s easier to guard against hot sockets and loss of efficiency can be stopped before they get started, making for happy customers and happier technicians.